Welcome

13503278266

PRODUCT CATEGORY

NEWS

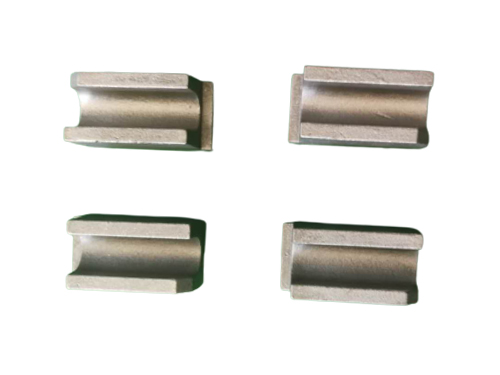

Counterweight iron

Counterweight iron is used to increase its own weight to maintain

balance. It is a technological process of melting the shot peening

machine into a liquid that meets the specified requirements and pouring

it into the mold. After cooling, solidification and cleaning, it can be

used for casting with predetermined shape, size and performance.

Counterweight iron is one of the basic processes in modern machinery

manufacturing industry.

Heavy industry counterweight iron is

generally classified according to modeling method, which is

traditionally divided into ordinary sand mold counterweight iron and

extra heavy iron. Common sand mold counterweight iron includes wet sand

mold, dry sand mold and chemical hardening sand mold. According to the

different molding materials, special counterweight iron can be divided

into two categories: one is natural growth mineral sand as the main

molding materials, such as investment mold counterweight iron, shell

mold counterweight iron, negative pressure counterweight iron, mud mold

counterweight iron, solid mold counterweight iron, ceramic mold

counterweight iron, etc; One is metal as the main mold material, such as

metal mold counterweight iron, centrifugal counterweight iron,

continuous counterweight iron, pressure counterweight iron, low pressure

counterweight iron, etc. Heavy industry counterweight iron process can

be divided into three basic parts, namely counterweight iron metal

preparation, mold preparation and casting treatment.

There is no

clear definition for the classification of counterweight iron in light

industry, which can be roughly divided into two categories. One is sheet

forming; One is profile processing. Materials mainly include various

plates, sheets, round iron, flat iron, square iron, other profiles, etc.